EVUlution AG

Smart grids made smarter

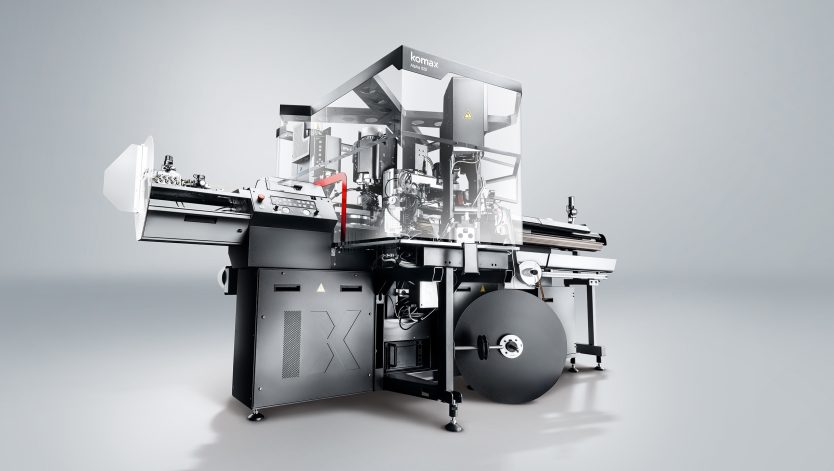

The Smart Manager by EVUlution AG monitors energy production and consumption while intelligently controlling connected devices in real time. As the system partner, we played a key role in developing this all-in-one electronic solution. Thanks to rapid prototyping, we accelerated the industrialization process and now produce the series version for the energy sector.

"With Variosystems, we’ve found a partner who speaks our language. We get the full range of services from a single source, that’s a perfect fit for us."

EVUlution AG

Founded in 2020 as a spin-off of Swiss energy provider Repower AG, EVUlution AG is based in Landquart and develops smart technologies for utilities and infrastructure operators. In close collaboration with Variosystems, the company developed the Smart Manager Gateway and the head-end system SMARTPOWER. Both the manufacturing and delivery of the devices are handled directly by Variosystems.

2018

4

4

10

2018

4

4

10

Building the foundation for a smarter energy future

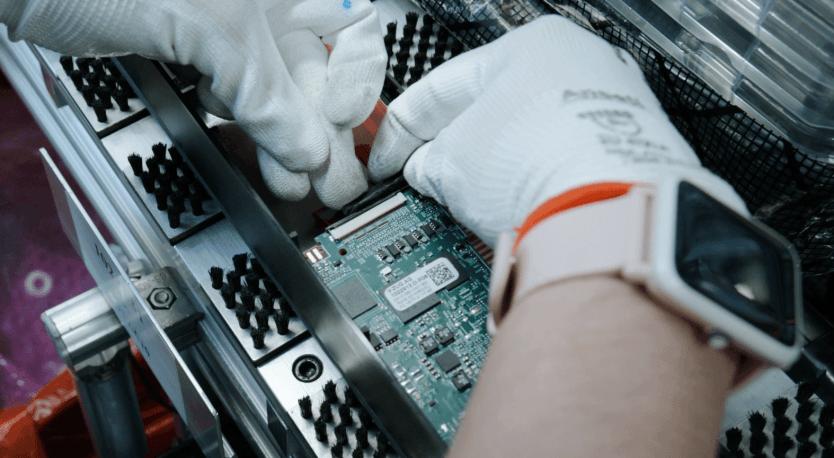

Local intelligence is the backbone of tomorrow’s energy grid. The Smart Manager from EVUlution collects real-time energy data and enables instant control of devices. Together with EVUlution, we developed the communication unit for the SMARTPOWER solution – drawing on nearly every part of our portfolio, from rapid prototyping and industrialization to full-scale series production.

Beyond a meter

Smart grids aim to make Switzerland’s electricity usage more transparent and efficient. Replacing analog meters with digital smart meters is just the first step. At the heart of the smart grid lies the Smart Meter Gateway – a compact computing unit that enables real-time monitoring and smart energy management. It automatically collects metering data, stores it locally, and securely transmits it to the head-end system (HES).

With SMARTPOWER, EVUlution has developed an integrated gateway and HES solution. As a co-creation partner from day one, we helped accelerate development significantly. “The Smart Manager enables real-time monitoring and intelligent device control. This promotes more conscious energy usage and incentivizes behavior that supports grid stability,” says Roger Caviezel, Head of SMARTPOWER at EVUlution.

From vision to production partner

The idea for the Smart Manager predates the founding of EVUlution. In fact, Roger Caviezel first envisioned the solution in 2017 while still at Repower, and reached out to us early on. “We had a clear vision and strategy paper – but we needed a capable partner to make it happen,” he recalls. That partner: Variosystems. Since 2018, our interdisciplinary Customer Success Team has supported the project from concept to reality – delivering results through rapid prototyping, industrialization, and scalable manufacturing.

Rapid prototyping for fast results

Our collaboration began with a functional prototype tailored to the desired interfaces and communication technologies. We selected components and designed a PCB layout for automated SMT assembly. Within just four weeks, we had a working prototype complete with housing and firmware. “We were under pressure to deliver early results. The team showed incredible drive and gave us exactly what we needed,” Caviezel notes. About 60 Smart Managers were then thoroughly tested.

Test engineering was a critical factor: each unit undergoes around 10 individual tests. “Reliability is key. Every faulty device in the field would mean expensive troubleshooting and replacement,” he explains. Parallel to the Smart Manager, EVUlution developed SMARTPOWER – a web-based software platform that combines smart metering, intuitive data management, and intelligent energy control in real time.

Flexible series production and direct delivery

Since 2020, we’ve been producing four versions of the Smart Manager in flexible batch sizes for Swiss utility providers. These are delivered directly to customers – labeled, branded, and sorted by serial number in multi-packs. “This service is essential for us. We don’t have a logistics department or warehousing. Our clients appreciate clean, clearly organized packaging – they know exactly what they’re receiving at a glance,” says Caviezel.

Interview with Roger Caviezel

We communicate on equal footing – and that’s what true partnership means. From the start, there was strong mutual interest. As soon as we presented the project and its requirements, Variosystems came back with practical, concrete solutions. It was clear they had hands-on experience and deep expertise. Plus, their site in Zizers – close to ours – was a major advantage.

The collaboration is personal, service-oriented, straightforward, and efficient. The Customer Success Team reacts quickly and flexibly to spontaneous changes. They’re continuously optimizing their services and supporting product development. When needed, the production team even works extra shifts.

We’re not hardware manufacturers, so we rely on strong partners. With Variosystems, we get everything from a single source – that’s ideal for us. Especially during the prototyping phase, they showed impressive dedication, provided expert advice, and delivered right on time. That was a key success factor.

It’s absolutely critical. We need to be able to trust the functionality and quality of every device. A defective product in the field means costly interventions. It would certainly be cheaper to manufacture in Asia – but we’d sacrifice performance. Variosystems shares our commitment to quality. As a company based in Graubünden, it was a conscious decision to work with a local Swiss partner in Zizers.

Whenever a component became unavailable, Variosystems proactively sourced reliable alternatives. This approach proved invaluable during the pandemic, when many parts became scarce or prohibitively expensive. Variosystems always found timely solutions. Even larger changes – like redesigning a PCB – were implemented quickly and seamlessly. Their handling was flawless.

We use cookies to enhance your experience on our website. If you continue browsing or click “Continue without consent”, only technically necessary cookies will be used. By clicking “Accept all cookies”, you also consent to marketing cookies. You can adjust your preferences under “Cookie settings”. Learn more in our Privacy Policy.

Cookie Settings

We use cookies to ensure the basic functionality of our website. You can choose to accept or reject cookies for each category.

We use cookies to ensure the basic functionality of our website. You can choose to accept or reject cookies for each category.

These cookies enable you and us to use the basic functionalities of our site. They are essential for the proper functioning of our website.

- Robot/spam detection

- YouTube embeds

- Language selection

- Server session handling for forms

- CSRF/authentication

- Other basic function cookies (e.g., session cookies for navigation and security)

Functional cookies allow the integration of external content on our pages, which you can use without leaving our website.

- Layout preference

- Newsletter signup form cookies (Mailchimp for subscription handling)

These cookies allow us to deliver personalized advertising and retargeting via external platforms. We use these cookies to continuously optimize our services and tailor them to your needs.

- Google Tag Manager

- Google Analytics

- Google Ads

- Google Ads Remarketing

- Google Conversion Tracking

- Microsoft Clarity

- Meta Pixel

- LinkedIn Insight Tag

- Mailchimp

Protecting your personal data is very important to us. Learn more in our Privacy Policy.

Sign up for our newsletter

We look forward to sending you regular information on what is happening at Variosystems.