From schematic to shipment: Electronic product development services without compromise

In electronics, speed is not just a luxury, it is a competitive edge. However, speed without quality? That is a recipe for headaches. We believe you should not have to choose. You can have both. And that’s where our innovative engineering team makes the difference—through integrated electronic product development services throughout the entire life cycle.

How our engineers keep electronics product design moving fast

When a customer brings us a product idea or design and a tight deadline, we don’t just take the circuit board blueprints and run. We roll up our sleeves and dive in early, right at the drawing board. Our mission is more than just turning a schematic into a reality. It’s ensuring your design is ready for scale and your product built with confidence and delivered on time.

This includes tight coordination across disciplines like PCB design services, software development, and embedded systems to ensure every aspect of the product works seamlessly together.

Starting smart: electronic design reviews that make a difference

It all begins with a Design for Manufacturability (DFM) review. This isn’t just a technical box to check; it’s the first step in a robust design process. We catch potential pitfalls before they become production delays. If a component is hard to source or a layout might cause testing issues, we flag it early.

We’ll sit down with you (virtually or in-person), walk through the product design, and offer practical tweaks to make sure everything flows smoothly later. This collaborative process to development avoids costly changes and keeps your new product introduction on track.

Building in quality with custom testing

One of the biggest value-adds our engineering team brings to the table is customized test development. No cookie-cutter solutions here! Whether it’s a simple test jig or a full functional test with embedded firmware, everything is tailored to your specific requirements.

Sometimes that means product design test fixtures from scratch. Sometimes we’re writing custom scripts or collaborating directly with your firmware team. It’s all about building in diagnostics that catch the right issues before your electronics product ever leaves our production line.

Rapid electronics prototyping, real-time learning

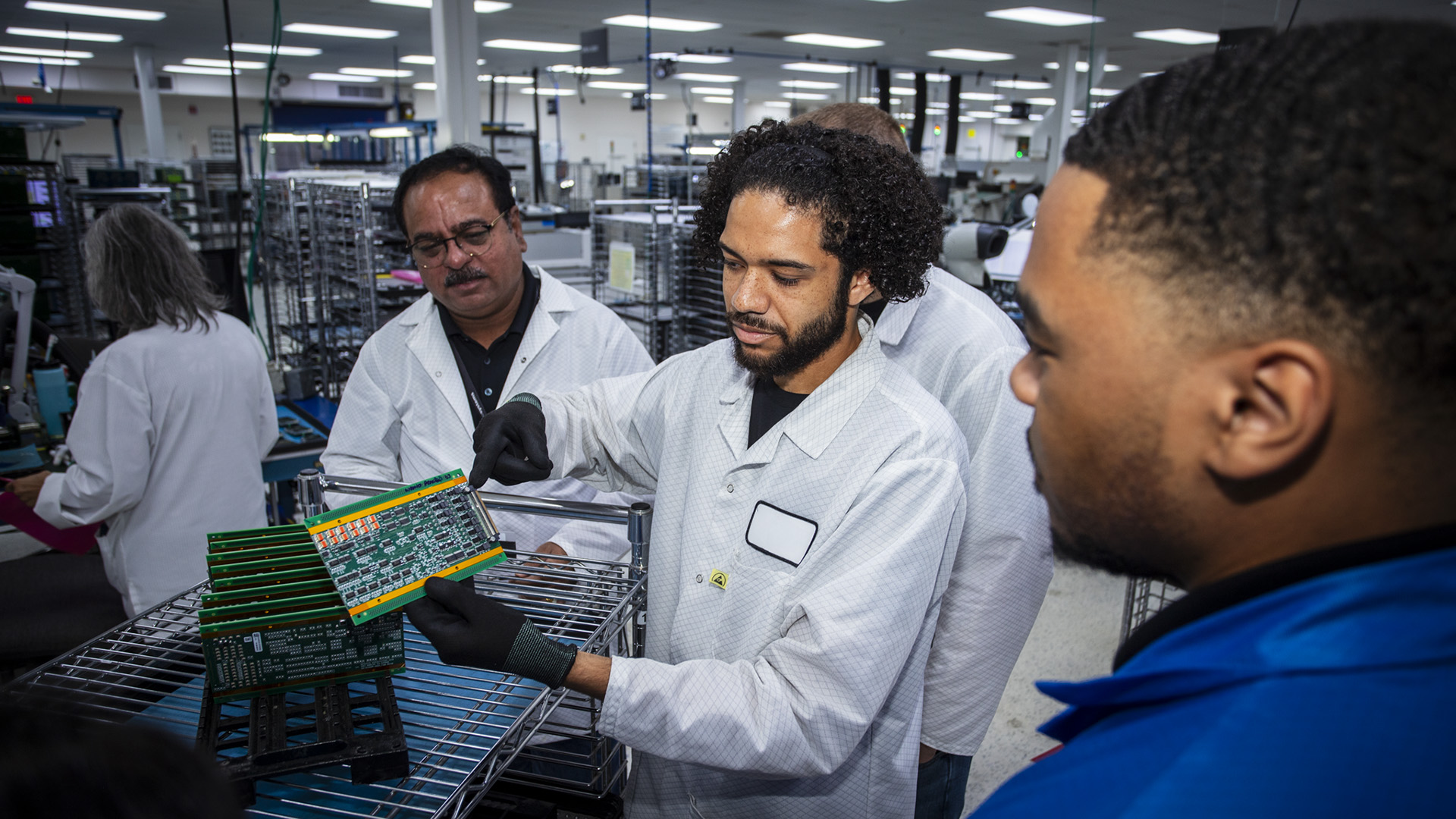

Pilot builds are where plans meet reality and they’re some of our most critical phases of any electronic product design process. Our engineers are right there on the production floor, monitoring every detail. If an issue pops up during testing, we’re troubleshooting it live. If there’s an opportunity to tighten the process, we’re on it.

This phase moves quickly, but we’re built for it. Our teams can make rapid adjustments without compromising quality, which helps keep momentum high and surprises low.

From the factory floor to the customer’s door

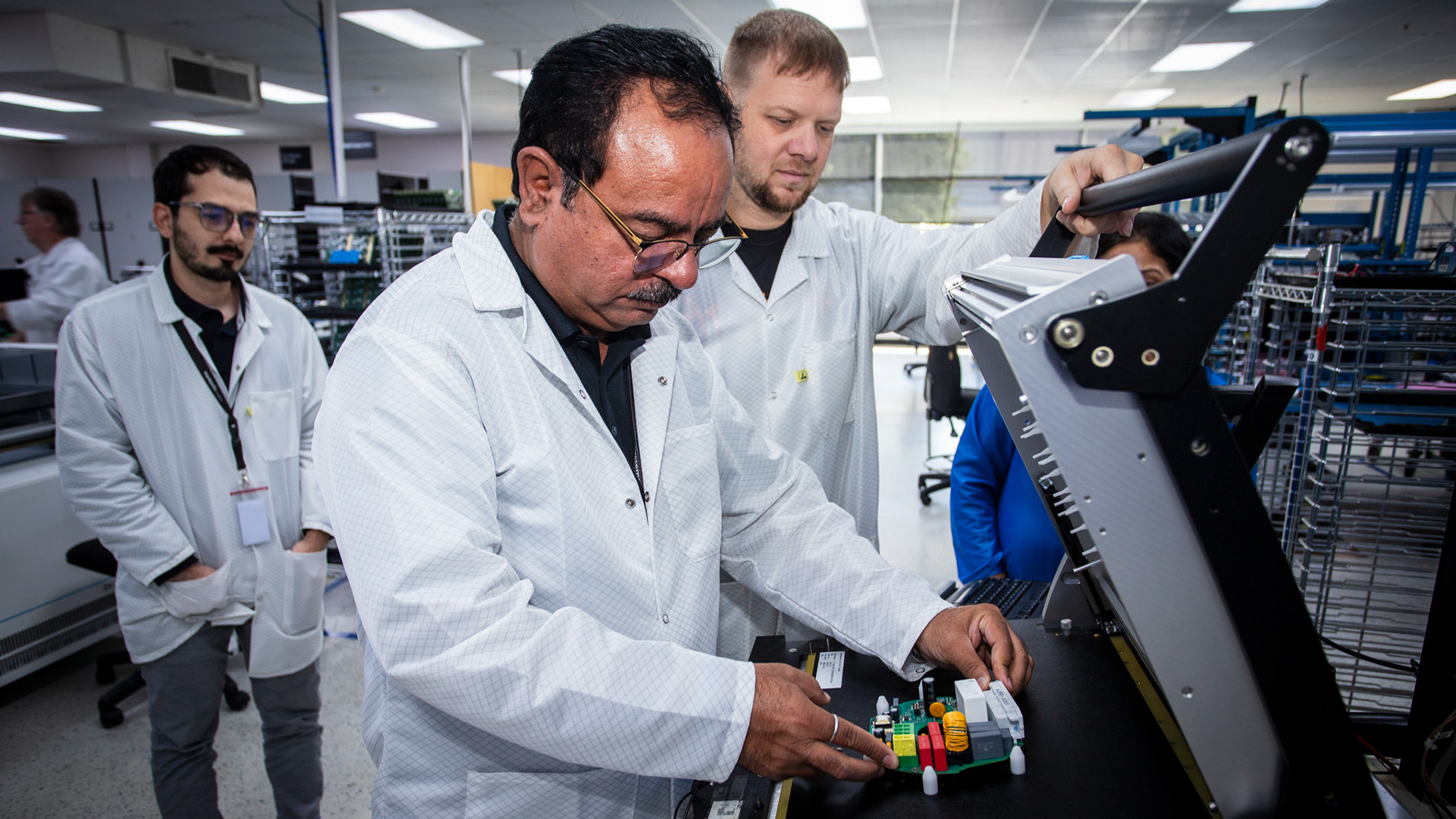

As we transition from electronics prototyping builds to full-scale production, our work doesn’t stop, it simply shifts focus. At this stage, we ensure traceability, compliance, and customer-specific delivery requirements are fully met.

Whether that means applying serialized labels, integrating with Manufacturing Execution Systems (MES), or packing products according to your specifications, our engineers are still hands-on. Even at the shipping stage, we’re making sure nothing slips through the cracks.

Electronic product development that powers progress

At Variosystems, engineering isn’t a handoff in the middle of the process. From the first spark of an idea to shipment, we are fully embedded in your electronic design services strategy. We are problem solvers, risk reducers, and your strategic EMS partner in accelerating your new product introduction faster with zero compromises on quality.

Looking for an electronics manufacturing services partner that takes engineering as seriously as you take your product? Let’s talk or check out our case studies on other customer projects to get a first idea about our co-creation approach.

Q&A

That is probably the most crucial question you are asking yourself. Since we understand how exciting new product ideas are, it is important to us to answer this question as quickly as possible. Early testing helps us to find a way to answer this soon. If a clear ‘yes’ isn’t possible at first glance, we’ll find a way to get there.

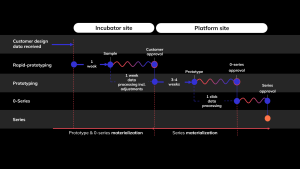

The stages of electronic product design and development follow a structured process.

Our electronic product development services include concept ideation, feasibility analysis, schematic design, PCB design services, prototype testing, regulatory compliance, and series production coordination. These services cover all aspects of the product development process to ensure a successful outcome. But our service is not done after your product has gone into production. We also offer you Life-Cycle Management.

Our integrated engineering and manufacturing approach enables rapid development without compromising quality. From initial design data to fully assembled and tested electronics in series production, we streamline every step to accelerate your time to market.

With more than 30 years of experience, we are a trusted global partner for high-quality electronics solutions. Focused on long-term success, we collaborate closely with today’s innovators to turn transformative ideas into reality through true co-creation. This approach drives our high-quality standards and ensures we consistently deliver on them.

Sangeeta is our Firmware Engineer III at the Variosystems Southlake site. She specializes in embedded systems design, automated testing and digital manufacturing—always seeking smarter ways to connect them. Beyond engineering, Sangeeta mentors students in STEM innovation programs, blending creativity and precision in everything she does.

We use cookies to enhance your experience on our website. If you continue browsing or click “Continue without consent”, only technically necessary cookies will be used. By clicking “Accept all cookies”, you also consent to marketing cookies. You can adjust your preferences under “Cookie settings”. Learn more in our Privacy Policy.

Cookie Settings

We use cookies to ensure the basic functionality of our website. You can choose to accept or reject cookies for each category.

We use cookies to ensure the basic functionality of our website. You can choose to accept or reject cookies for each category.

These cookies enable you and us to use the basic functionalities of our site. They are essential for the proper functioning of our website.

- Robot/spam detection

- YouTube embeds

- Language selection

- Server session handling for forms

- CSRF/authentication

- Other basic function cookies (e.g., session cookies for navigation and security)

Functional cookies allow the integration of external content on our pages, which you can use without leaving our website.

- Layout preference

- Newsletter signup form cookies (Mailchimp for subscription handling)

These cookies allow us to deliver personalized advertising and retargeting via external platforms. We use these cookies to continuously optimize our services and tailor them to your needs.

- Google Tag Manager

- Google Analytics

- Google Ads

- Google Ads Remarketing

- Google Conversion Tracking

- Microsoft Clarity

- Meta Pixel

- LinkedIn Insight Tag

- Mailchimp

Protecting your personal data is very important to us. Learn more in our Privacy Policy.

Sign up for our newsletter

We look forward to sending you regular information on what is happening at Variosystems.