ENGEL AUSTRIA GmbH

Software specialist for the plastics industry

In today's era of digital transformation, manufacturing execution systems (MES) are a key success factor for modern production companies. The MES solution authentig was specifically developed for the needs of the injection molding industry and acts as a central interface between the ERP system and the shop floor.

"With our new web application, we offer customers a flexible and future-proof solution for efficiently managing their production processes. The intuitive user interface provides direct access to all relevant data and enables customized workflows. Thanks to the close collaboration with Variosystems, we were able to develop a modern, platform-independent solution that meets the highest industry standards."

ENGEL AUSTRIA GmbH

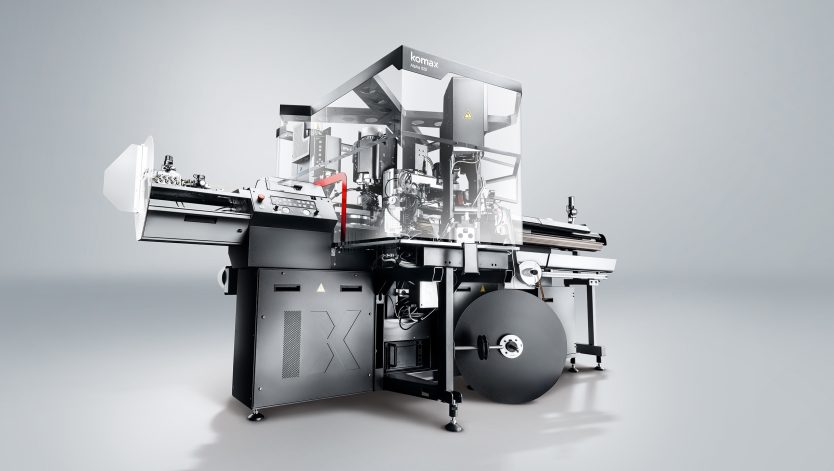

ENGEL AUSTRIA GmbH is a leading manufacturer of injection molding machines. In addition to machinery, ENGEL also offers automation systems and solutions. The company has also developed its own MES software solution called authentig, which is continuously enhanced at its Rankweil site in Austria.

PC, tablet, phone

Flexible

Simple integration

PC, tablet, phone

Flexible

Simple integration

Expertise in software engineering

With in-depth practical experience in web application development and deep domain knowledge from its existing MES solution, ENGEL decided to collaborate with us on the concept and implementation of a new web-based application. The goal of the project was to leverage modern technologies and integrate our web development expertise directly into ENGEL’s in-house software team.

User and communication interface

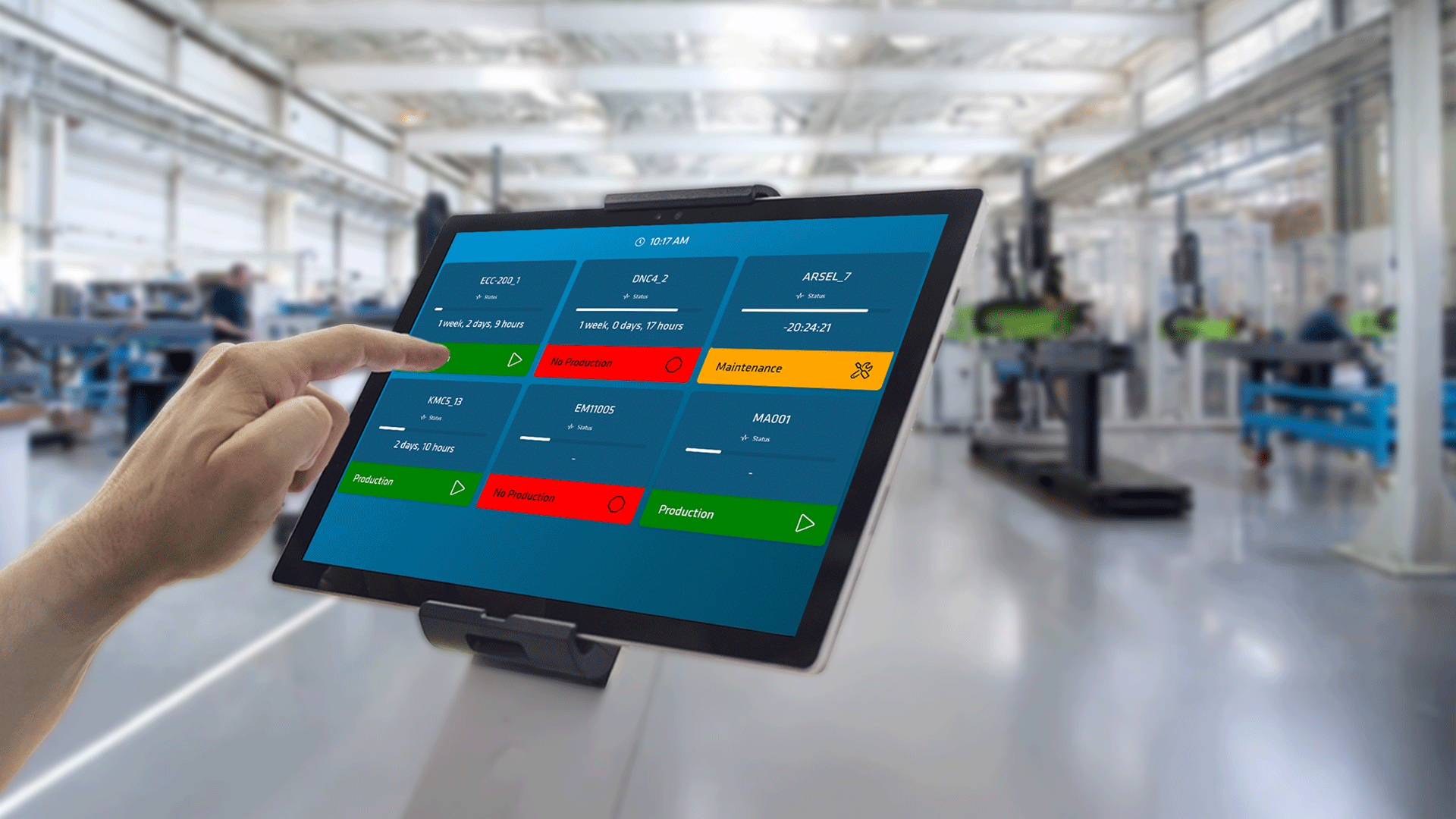

A user-friendly and clearly structured interface is essential as the communication layer between humans and machines. With just a few clicks, users should be able to access critical KPIs such as productivity, cycle times, scrap rates, and machine utilization. In addition, they should be able to view, start, split, or stop production orders with minimal effort.

Flexible and platform-independent

While the previous MES interface served its purpose, it offered limited flexibility due to the underlying technologies. Custom adaptations were time-consuming and complex. Today’s manufacturing environments require adaptable and scalable user interfaces. The new solution is a standardized product that can easily be tailored to specific customer requirements. To meet this demand, a flexible, platform-independent solution based on web technologies was developed.

All data at a glance

The requirements for the new web application were extensive—both from ENGEL and its customers. Central to the new development were flexibility and the ability to customize clients and workflows. Another key focus was the seamless integration of additional interfaces, such as REST APIs or RPC, to enrich order-related data. To meet these demands, a flexible platform was developed that can be configured and tailored to customer needs during system commissioning.

The user interface of the SiMES web application can be flexibly configured and displays all relevant production data, including log entries, order status, and maintenance schedules. Adaptations for individual clients and workflows can even be made at runtime.

The digital factory becomes reality

ENGEL now benefits from a modern and highly flexible user interface, making it well-equipped for future Smart Factory requirements. A single terminal can be used to operate multiple machines. Key performance indicators such as productivity, cycle time, scrap rate, and utilization are presented in a clear and accessible format. Thanks to the platform-independent web implementation, it doesn’t matter whether the user is on a PC, tablet, or smartphone.

With our deep expertise in both system and web application development, we made a significant contribution to delivering a flexible and user-friendly tool that can be easily adapted to meet the specific needs of ENGEL’s customers.

We use cookies to enhance your experience on our website. If you continue browsing or click “Continue without consent”, only technically necessary cookies will be used. By clicking “Accept all cookies”, you also consent to marketing cookies. You can adjust your preferences under “Cookie settings”. Learn more in our Privacy Policy.

Cookie Settings

We use cookies to ensure the basic functionality of our website. You can choose to accept or reject cookies for each category.

We use cookies to ensure the basic functionality of our website. You can choose to accept or reject cookies for each category.

These cookies enable you and us to use the basic functionalities of our site. They are essential for the proper functioning of our website.

- Robot/spam detection

- YouTube embeds

- Language selection

- Server session handling for forms

- CSRF/authentication

- Other basic function cookies (e.g., session cookies for navigation and security)

Functional cookies allow the integration of external content on our pages, which you can use without leaving our website.

- Layout preference

- Newsletter signup form cookies (Mailchimp for subscription handling)

These cookies allow us to deliver personalized advertising and retargeting via external platforms. We use these cookies to continuously optimize our services and tailor them to your needs.

- Google Tag Manager

- Google Analytics

- Google Ads

- Google Ads Remarketing

- Google Conversion Tracking

- Microsoft Clarity

- Meta Pixel

- LinkedIn Insight Tag

- Mailchimp

Protecting your personal data is very important to us. Learn more in our Privacy Policy.

Sign up for our newsletter

We look forward to sending you regular information on what is happening at Variosystems.