Waterproof PCB coating – How to protect your circuit boards from moisture

Whether in industrial plants, vehicles, aircraft, or medical devices, printed circuit boards (PCBs) are the beating heart of every electronic system. For PCBs to deliver reliable performance over the long term, they must be effectively protected from moisture and harsh environments. Even tiny amounts of water can lead to corrosion, short circuits, or complete system failures.

Why waterproof PCB coating matters

Moisture is one of the most common failures of electronic components. Condensation or high humidity alone is often enough to damage sensitive electronics. This risk is especially critical in safety-relevant applications such as medical technology, aerospace, or industrial control systems. That’s why waterproof PCB coating is essential for long-lasting protection.

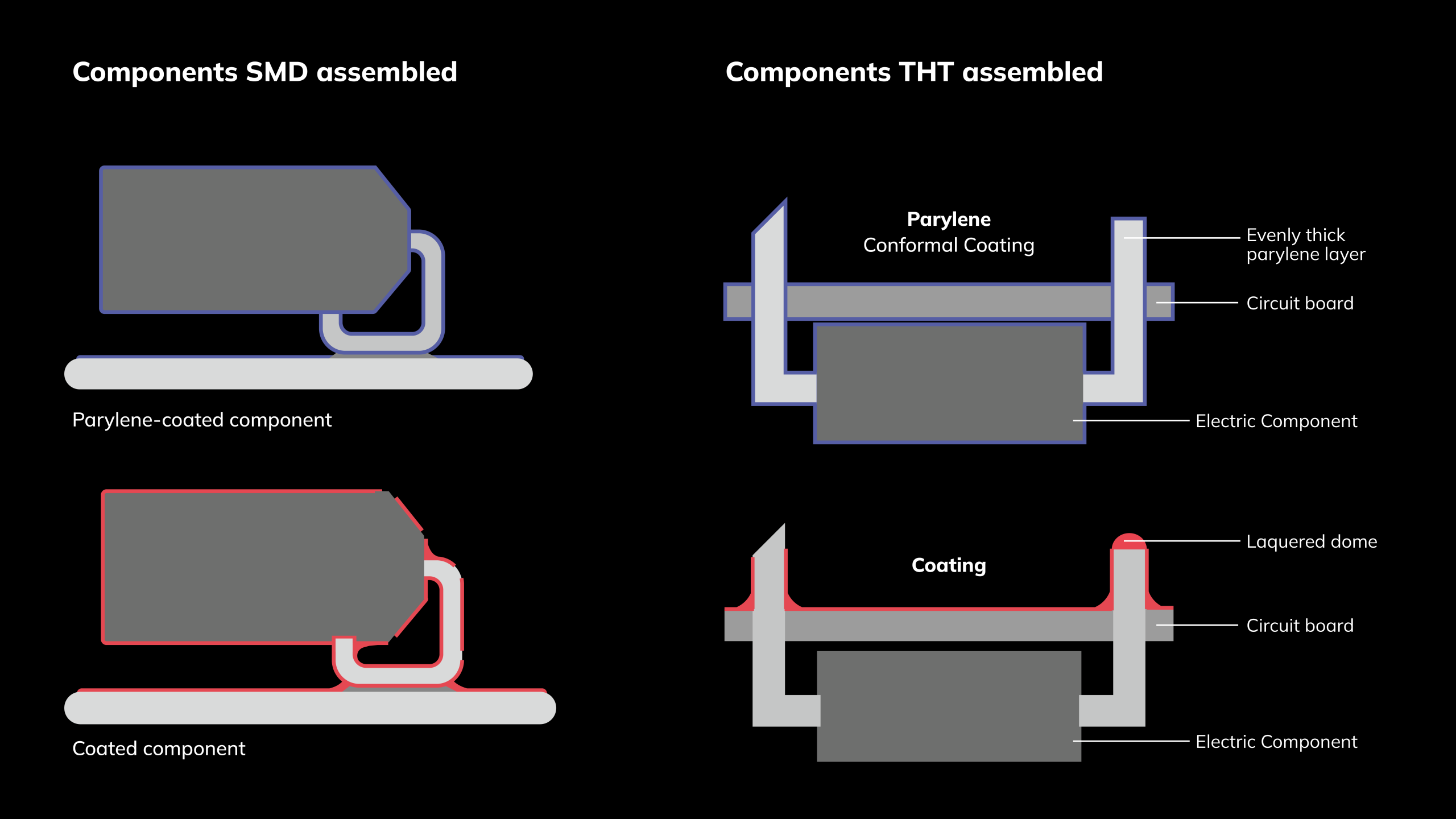

methods such as protective varnishes or potting compounds often cannot meet all requirements: Varnishes may not fully reach complex geometries, while potting makes repairs difficult and increases weight. The answer: parylene waterproof PCB coating – a highly uniform, thin, and durable coating layer film.

What is parylene and why is it used?

Parylene is an ultra-pure polymer that can be applied using various methods, including vapor deposition inside a vacuum chamber. This process creates a uniform, pinhole-free film that penetrates even the smallest gaps, cavities, and spaces beneath components. Unlike liquid conformal coatings, the gas-phase deposition ensures that sharp edges, fine tips, and narrow gaps are completely covered. Even the undersides of components such as BGAs (Ball Grid Array) or QFPs (Quad Flat Package) can be sealed reliably.

Key benefits of parylene waterproof PCB coating:

- Outstanding resistance to moisture, chemicals, and harsh environments

- Excellent electrical insulation with high dielectric strength

- Reduced whisker growth due to a continuous insulation layer

- Biocompatibility – ideal for medical applications

- Transparent, ultra-thin film – perfect for complex assemblies

Parylene can be applied to almost any vacuum-compatible substrate: metals, plastics, ceramics, glass, rubber, or silicone.

How the parylene coating process works

The parylene waterproof PCB coating process uses chemical vapor deposition (CVD) in a vacuum chamber – completely solvent-free and without mechanical application. The workflow includes several carefully controlled steps:

- Cleaning – The assemblies are cleaned to eliminate any residues that could affect the bonding of the Parylene layer. This provides protection against parylene vapor.

- Masking – Critical zones like connectors or test points are selectively covered to keep them free from coating.

- Deposition – In a vacuum chamber, Parylene vapor forms a seamless protective layer over the entire assembly. Depending on the desired thickness, this process takes between 12 and 20 hours. The molecules attach themselves evenly and seamlessly, even in complex geometries.

- Demasking – After conformal coating, the masked areas are precisely uncovered. For very fine structures, advanced laser technology is used to remove the film with micrometer accuracy.

- Inspection – The coating is then thoroughly tested: in addition to a visual inspection to ensure uniformity and complete coverage, the layer thickness is verified using separate measuring plates. The adhesion of the parylene layer is also checked using a cross-cut test on samples that have been treated throughout the entire process. All machine and process parameters are documented to ensure traceability and process stability.

By the way, did you know that we are Europe’s leading specialist in conformal coating and the only provider offering laser demasking for ultra-fine geometries?

Types of parylene

- Parylene C (< 100°C): Low moisture permeability, strong chemical resistance – widely used in industrial electronics and medical devices.

- Parylene F (> 200°C): High chemical resistance, low friction – mainly suitable for microelectromechanical systems and nanotechnology applications.

- Parylene N (< 70°C): Excellent dielectric insulation, superior penetration – ideal for sensors, microelectronics, and medical devices.

- Parylene D (< 150°C): High temperature stability – perfect for automotive and aerospace electronics.

- Parylene AF-4 / HT (> 350°C): Exceptional UV and chemical resistance up to 450°C – used in space technology and high-frequency systems.

Advantages of waterproof PCB coating with parylene

Compared to conventional methods, Parylene offers unmatched benefits:

- Seamless coverage of complex geometries

- Uniform thickness thanks to the CVD process

- No thermal stress – safe for heat-sensitive components

- Effective barrier against moisture, gases, chemicals, and microbes

- Long-term durability, abrasion resistance, and stability under extreme conditions (92 A Shore)

- Biocompatibility and transparency for medical and optical uses

Compared to other methods:

- More reliable than liquid conformal coatings, especially in hard-to-reach areas

- Lighter and selectively removable compared to potting compounds

- Ideal when protection and quality are the priority

For applications with the highest quality and verification requirements

Most types of parylene are qualified according to the US military standard MIL-I-46058C – a standard that is no longer actively used for new designs but continues to serve as a benchmark for retrofits and existing solutions. Most of these coatings also meet the requirements of current industry standards such as IPC-CC-830, which is now considered the benchmark for conformal coatings in sensitive applications.

Together with our EN9100 certification, we offer you a reliable solution for demanding projects in aerospace and defense applications.

Typical applications

Parylene waterproof PCB coating is widely used across industries:

- Electronics: PCBs, sensors, and assemblies

- Medical Technology: catheters, stents, implants

- Aerospace: highly reliable mission-critical systems

- Automotive: control units, batteries, and EV components

- Railway & Mining: extreme environments with moisture and dust

- Document Protection: long-term sealing solutions

Compatible with metals, plastics, silicones, rubber, glass, and ceramics.

Conclusion: parylene coating provides reliable, long-lasting water protection for circuit boards

Parylene coating is the go-to solution when reliability, durability, and precision are critical. The coating is particularly useful where other methods reach their limits. The process is more complex than applying a coating, but it is often more cost-effective than a complete encapsulation solution and more practical than a waterproof housing, for example. The most important factors determining the price are:

- PCB geometry and processing time

- Manual masking effort for sensitive areas

- Type of parylene used

It’s worth investing in parylene waterproof PCB coating if:

- You need long-term protection in harsh conditions

- Complex assemblies require uniform sealing

- Biocompatibility or transparency is needed

- Repairability and low weight are important

If you need waterproof PCBs and want to rely on a proven coating method, Parylene is a reliable solution—versatile, long-term stable, and industry-proven.

Q&A

They protect electronics from water, moisture, condensation, and harsh environments, significantly increasing reliability, extending service life, and reducing risks of corrosion or short circuits.

In medical devices (implants, catheters), automotive and EV systems, aerospace, mining, railway technology, and industrial systems exposed to humidity or chemicals.

Whenever an electronic assembly must remain reliable under harsh conditions – such as exposure to water, humidity, chemicals, temperature shifts, or when biocompatibility is required. Parylene conformal coating is particularly useful for miniaturized designs or areas that are difficult to access.

Common conformal coatings are:

- Acrylic: inexpensive, easy to process

- Silicone: flexible, heat-resistant

- Polyurethane: chemical-resistant

- Epoxy resin: hard, robust, difficult to remove

- Parylene: gas phase-based, ultra-thin, seamless—ideal for the highest requirements in terms of tightness and geometric coverage

Yes, they can create stress that causes cracks or delamination. Parylene’s flexibility and thermal stability ensure long-lasting functionality even under extreme temperature changes.

We use cookies to enhance your experience on our website. If you continue browsing or click “Continue without consent”, only technically necessary cookies will be used. By clicking “Accept all cookies”, you also consent to marketing cookies. You can adjust your preferences under “Cookie settings”. Learn more in our Privacy Policy.

Cookie Settings

We use cookies to ensure the basic functionality of our website. You can choose to accept or reject cookies for each category.

We use cookies to ensure the basic functionality of our website. You can choose to accept or reject cookies for each category.

These cookies enable you and us to use the basic functionalities of our site. They are essential for the proper functioning of our website.

- Robot/spam detection

- YouTube embeds

- Language selection

- Server session handling for forms

- CSRF/authentication

- Other basic function cookies (e.g., session cookies for navigation and security)

Functional cookies allow the integration of external content on our pages, which you can use without leaving our website.

- Layout preference

- Newsletter signup form cookies (Mailchimp for subscription handling)

These cookies allow us to deliver personalized advertising and retargeting via external platforms. We use these cookies to continuously optimize our services and tailor them to your needs.

- Google Tag Manager

- Google Analytics

- Google Ads

- Google Ads Remarketing

- Google Conversion Tracking

- Microsoft Clarity

- Meta Pixel

- LinkedIn Insight Tag

- Mailchimp

Protecting your personal data is very important to us. Learn more in our Privacy Policy.

Sign up for our newsletter

We look forward to sending you regular information on what is happening at Variosystems.