Durst Group AG

Strong partnership for a resilient supply chain

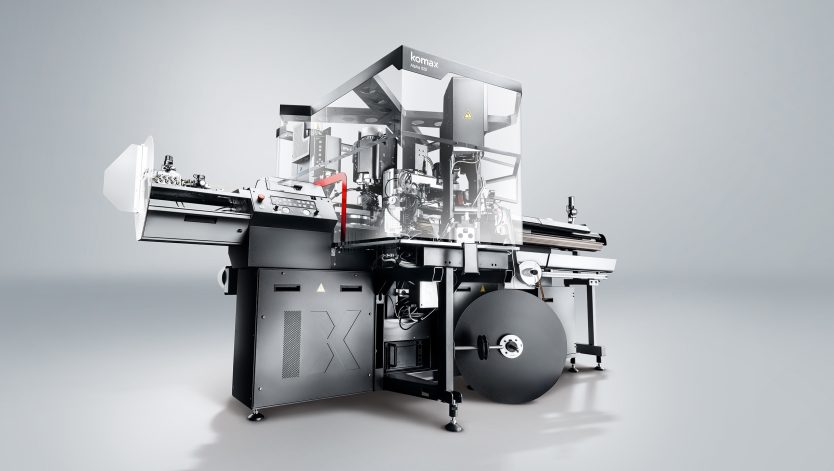

To manufacture its electronic assemblies, the globally leading provider of digital printing and production technologies, Durst Group AG, was looking for a partner that could combine quality, flexibility, and technological expertise. Thanks to a structured collaboration, fast integration, and high manufacturing quality, production was seamlessly scaled. Today, the partnership covers multiple assemblies and box build projects, with a clear outlook for long-term cooperation.

"Durst Group is committed to the highest quality standards and technological innovation. We need reliable and flexible partners capable of precisely meeting our requirements for electronic assemblies. Variosystems not only offers excellent manufacturing expertise but also a deep understanding of our specific needs in PCB production."

Durst Group AG

Durst Group AG is one of the world's leading providers of digital printing and production technologies. Founded in 1936 and headquartered in Brixen, South Tyrol, the company employs more than 1,100 people worldwide. Its core business is digital inkjet printing, supported by a comprehensive ecosystem of inks, software, and services. As an innovation leader, the company operates three R&D centers and two innovation hubs.

8

Language skills

Excellence

8

Language skills

Excellence

Flexibility, quality, scalability

In 2023, Durst Group set out to reduce its dependency on a single supplier and build a more resilient supply chain. Following a thorough selection process, the company chose Variosystems as its second partner for electronic assemblies.

Fast transfer and seamless integration

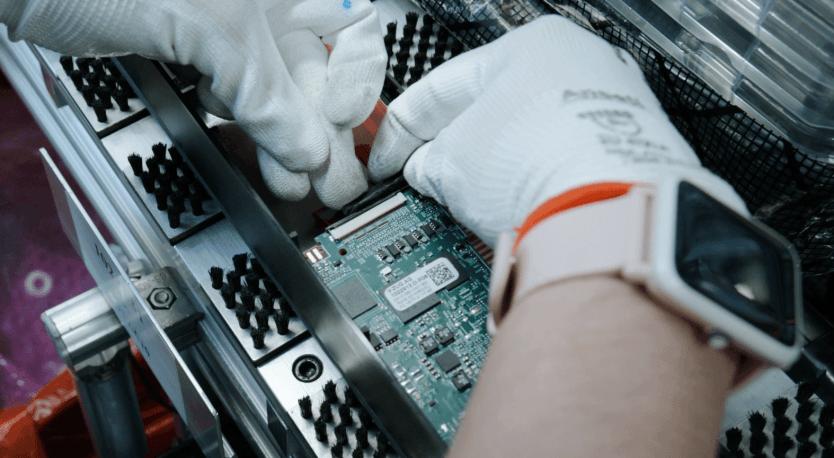

Once the decision was made, implementation followed swiftly. Initial pilot projects with prototypes, qualifications, and rapid approvals led to the series production of the first assemblies—PCBs for printing systems. Today, the project already includes more than eight assemblies, including two full box build projects.

“From the very beginning, the collaboration was structured and efficient. Through close communication between teams, requirements were quickly defined and integrated into existing processes. Variosystems showed great adaptability and actively supported us in optimizing our designs for smooth production,” says Überbacher.

Tackling challenges with agility

At Variosystems, sales, engineering, and procurement operate within clearly defined responsibilities, yet maintain close collaboration and ongoing communication. This interdisciplinary approach and focused communication with Durst Group’s contact persons allow for quick and effective problem-solving.

“Our assemblies demand precision, reliability, and an extremely low failure rate. Alongside high production quality, process stability, long-term availability, and flexibility are key,” Überbacher explains. Naturally, any transfer comes with challenges. Thanks to Variosystems’ agile Customer Success Team, issues such as sudden material shortages or tight delivery deadlines could be swiftly resolved.

Global reach, local support – an optimized supply chain

“The combination of global reach and local support has proven to be a clear advantage for us. We benefit from fast response times, dedicated points of contact, and access to an international production network,” says Überbacher.

Next steps – deepening co-creation

As a system partner, Variosystems supports layout services, custom test concepts, product development, industrialization, and ramp-up to series production. Their test engineering expertise ensures that potential failure points are identified and eliminated early—laying the groundwork for a strong and future-oriented partnership.

Durst Group AG clearly sees this potential and wants to involve Variosystems in new developments from the outset: “Working with Variosystems has proven extremely valuable, and we see great potential to deepen the partnership further. Our focus is on driving innovation together, optimizing processes, and developing sustainable solutions for our customers,” says Überbacher.

In conversation with Simon Überbacher

Durst Group is committed to the highest quality and technological innovation. We need reliable and flexible partners capable of precisely delivering our requirements for electronic assemblies. Variosystems offers not only strong manufacturing capabilities but also a deep understanding of our specific needs in PCB production.

The collaboration was structured and efficient from the start. Close exchange between the teams enabled us to quickly define requirements and integrate them into existing processes. Variosystems showed strong adaptability and actively supported us in optimizing our designs for smooth production.

Our assemblies require precision, reliability, and an extremely low failure rate. Alongside high manufacturing quality, we also rely on process security, long-term availability, and flexibility. Variosystems meets these expectations through cutting-edge production technologies, a robust quality management system, and close cooperation with us.

Thanks to our close cooperation with Variosystems, we benefit from a production strategy that’s already considered in the development phase. This not only allows for more efficient production and faster market launch but also lowers production costs. For our sales team, this means we can offer customers more reliable and cost-effective products.

The combination of global presence and local support has proven a clear advantage. We benefit from quick response times, close collaboration with dedicated contacts, and access to an international production network.

Working with Variosystems has been extremely valuable, and we see great potential for further deepening the partnership. Our focus is on advancing innovation together, continuously optimizing processes, and developing sustainable solutions for our customers.

We use cookies to enhance your experience on our website. If you continue browsing or click “Continue without consent”, only technically necessary cookies will be used. By clicking “Accept all cookies”, you also consent to marketing cookies. You can adjust your preferences under “Cookie settings”. Learn more in our Privacy Policy.

Cookie Settings

We use cookies to ensure the basic functionality of our website. You can choose to accept or reject cookies for each category.

We use cookies to ensure the basic functionality of our website. You can choose to accept or reject cookies for each category.

These cookies enable you and us to use the basic functionalities of our site. They are essential for the proper functioning of our website.

- Robot/spam detection

- YouTube embeds

- Language selection

- Server session handling for forms

- CSRF/authentication

- Other basic function cookies (e.g., session cookies for navigation and security)

Functional cookies allow the integration of external content on our pages, which you can use without leaving our website.

- Layout preference

- Newsletter signup form cookies (Mailchimp for subscription handling)

These cookies allow us to deliver personalized advertising and retargeting via external platforms. We use these cookies to continuously optimize our services and tailor them to your needs.

- Google Tag Manager

- Google Analytics

- Google Ads

- Google Ads Remarketing

- Google Conversion Tracking

- Microsoft Clarity

- Meta Pixel

- LinkedIn Insight Tag

- Mailchimp

Protecting your personal data is very important to us. Learn more in our Privacy Policy.

Sign up for our newsletter

We look forward to sending you regular information on what is happening at Variosystems.