V-ZUG AG

Swiss precision meets global flexibility

V-ZUG AG depends on the reliability of our electronic assemblies when manufacturing high-quality household appliances. These ensure full functionality and support V-ZUG’s philosophy of always providing the utmost quality.

"We receive assemblies that meet our high quality requirements, support us in our quest for greater sustainability and still offer us good value for money."

V-Zug AG

V-ZUG is the leading Swiss brand for household appliances and markets its products in carefully selected international premium markets. V-ZUG has been developing and producing appliances for the kitchen and utility room in Switzerland since it was founded in 1913 and offers an end-to-end service in all its markets. The V-ZUG Group currently employs around 2,100 people.

2010

Local presence

100%

2010

Local presence

100%

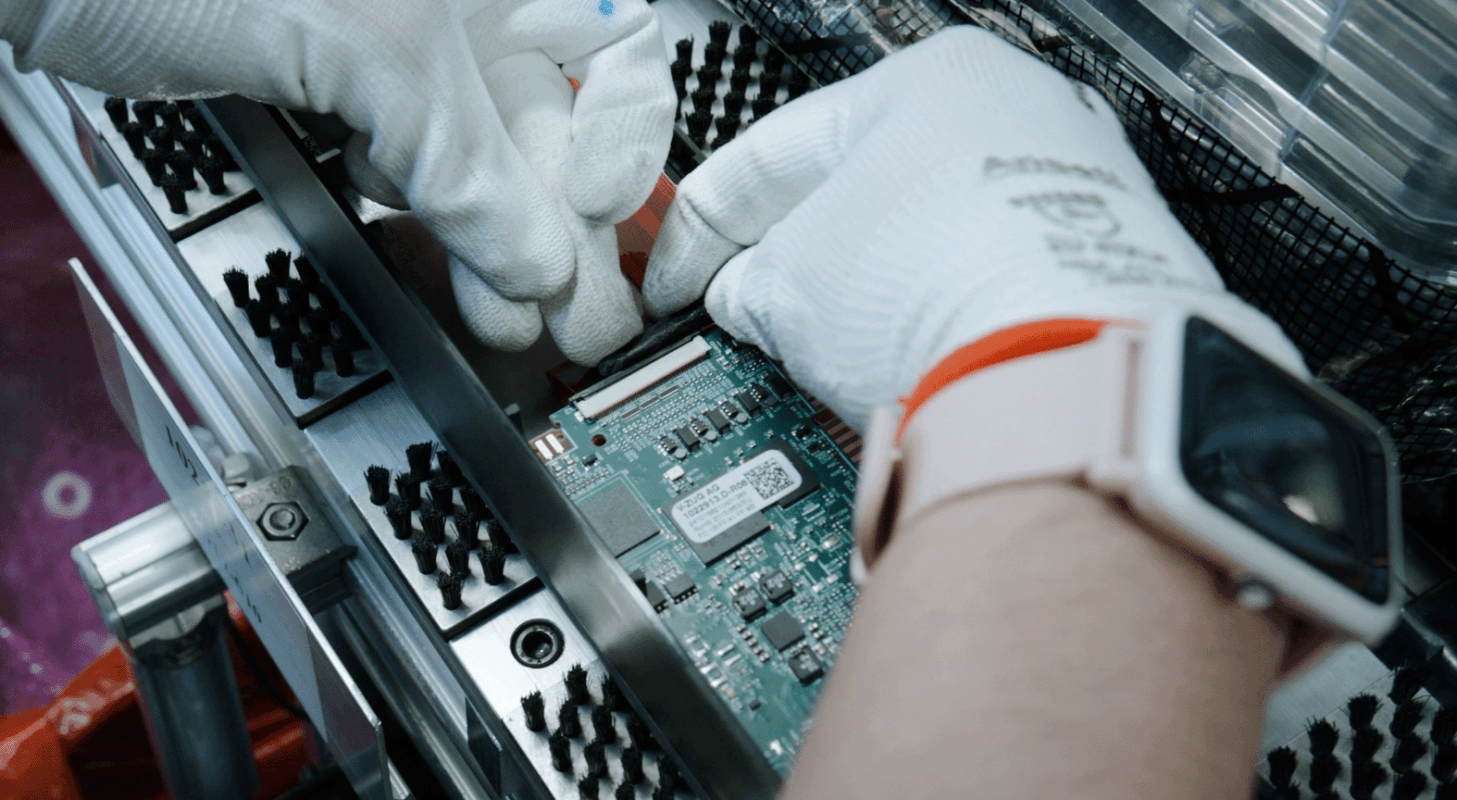

Made in Switzerland: High-quality assemblies for luxury household appliances

V-ZUG AG has been producing durable household appliances for the kitchen and textile care mainly in Switzerland since 1913 to this day. We supply several large series of electronic assemblies that are installed in washing machines and tumble dryers – in display controls, for example. V-ZUG benefits from our comprehensive functional tests and our global supply chain, which guarantees a seamless supply of high-quality electronic components.

Precision, quality and elegance

While other Swiss manufacturing companies are increasingly relocating their production to more cost-effective foreign countries, V-ZUG AG continues to rely on "Made in Switzerland". The company has been manufacturing kitchen and textile care appliances in Switzerland since 1913. Design, development and manufacturing are still largely carried out at the company's home base. "This is where our roots are. Our connection with Switzerland is anchored into the DNA of our brand," says Wolfgang Schroeder, Chief Technology Officer at V-ZUG AG. The company has made a conscious decision to stay in Switzerland. "By doing this, we are living out our Swiss identity and making a contribution to the local economy. Every product that is manufactured here is a symbol of our Swiss values: Precision, quality and elegance."

Long-term partnership and flexibility

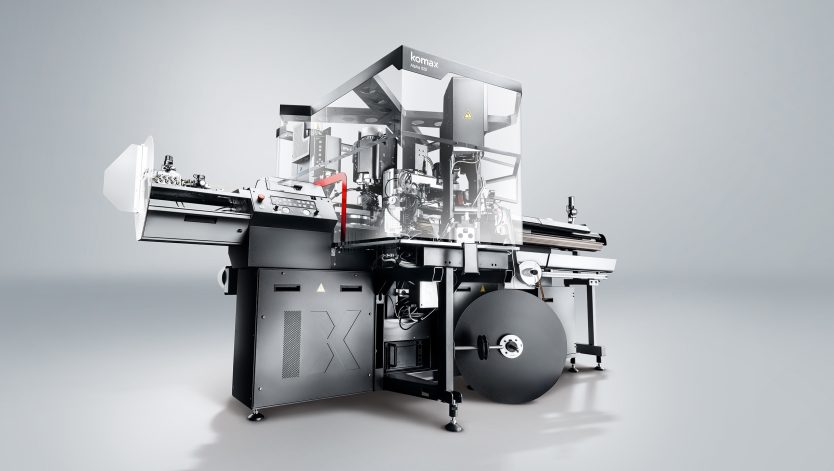

The collaboration began in 2010 with a small series and developed into a stable partnership with several large series. We manufacture electronic assemblies that are mainly installed in washing machines and tumble dryers – in display controls, for example. Adrian Rosenberger, Strategic Buyer at V-ZUG and the main person responsible for electronics purchasing, emphasizes our flexibility in particular. He also draws attention to our ability to deliver reliably even in times of crisis and to implement changes quickly at short notice. "While large EMS providers strictly follow their predefined processes, Variosystems does things in a straightforward way, adapting the required PCBs for us within a very short time. We benefit greatly from this flexibility and responsiveness."

Individual functional test concepts for comprehensive tests

The engineers at V-ZUG set out the design, functional models and parts lists for the assemblies. Based on this, we then create the prototypes, which are transferred to series production by our Technical Program Managers. Depending on the assembly and requirements, we use both surface-mount and through-hole technology. We then test all electronic assemblies for complete functionality – with individual functional test concepts including customer-specific test adapters. This is how we manage to reduce the failure rate to an absolute minimum.

Global supply chain and local presence

V-ZUG has access to a global supply chain via our Platform’s production network. "Thanks to this setup, we always receive top-quality components from all over the world and benefit from competitive procurement costs", says Rosenberger. This is a key aspect of our partnership, as V-ZUG carries out part of the final assembly of some components in China. "It was a basic requirement for us to work with regional partners in both Switzerland and China," says Rosenberger. In this way, our local Customer Success teams in Switzerland and China provide V-ZUG with optimum support in its nearshoring efforts. "The local exchange shortens and simplifies communication channels considerably. This means we are looked after closely worldwide."

In conversation with Adrian Rosenberger

Even during availability crises, Variosystems has proven to be a very reliable supplier – for example, for short-term software or hardware adaptations in our series development. While large EMS providers strictly follow their predefined processes, Variosystems does things in a straightforward way, customizing a PCB for us within a few weeks.

For example, we source printed circuit boards from the Platform sites in Switzerland, China and Sri Lanka. It means we have access to various procurement sources all over the world. In this way, we receive assemblies that meet our high quality requirements, support us in our quest for greater sustainability and still offer us good value for money.

These short communication channels within the same culture and time zone make the exchange much easier. Our contacts are competent, respond quickly and deliver exactly what we need. We’re very well looked after.

Very important. It’s usually very time-consuming to redesign device elements or assemblies and to go through all the necessary approvals. Variosystems has always informed us proactively and at an early stage about potential changes.

We use cookies to enhance your experience on our website. If you continue browsing or click “Continue without consent”, only technically necessary cookies will be used. By clicking “Accept all cookies”, you also consent to marketing cookies. You can adjust your preferences under “Cookie settings”. Learn more in our Privacy Policy.

Cookie Settings

We use cookies to ensure the basic functionality of our website. You can choose to accept or reject cookies for each category.

We use cookies to ensure the basic functionality of our website. You can choose to accept or reject cookies for each category.

These cookies enable you and us to use the basic functionalities of our site. They are essential for the proper functioning of our website.

- Robot/spam detection

- YouTube embeds

- Language selection

- Server session handling for forms

- CSRF/authentication

- Other basic function cookies (e.g., session cookies for navigation and security)

Functional cookies allow the integration of external content on our pages, which you can use without leaving our website.

- Layout preference

- Newsletter signup form cookies (Mailchimp for subscription handling)

These cookies allow us to deliver personalized advertising and retargeting via external platforms. We use these cookies to continuously optimize our services and tailor them to your needs.

- Google Tag Manager

- Google Analytics

- Google Ads

- Google Ads Remarketing

- Google Conversion Tracking

- Microsoft Clarity

- Meta Pixel

- LinkedIn Insight Tag

- Mailchimp

Protecting your personal data is very important to us. Learn more in our Privacy Policy.

Sign up for our newsletter

We look forward to sending you regular information on what is happening at Variosystems.